Pillow Fort

Boffo Building Fashion Competition, New York

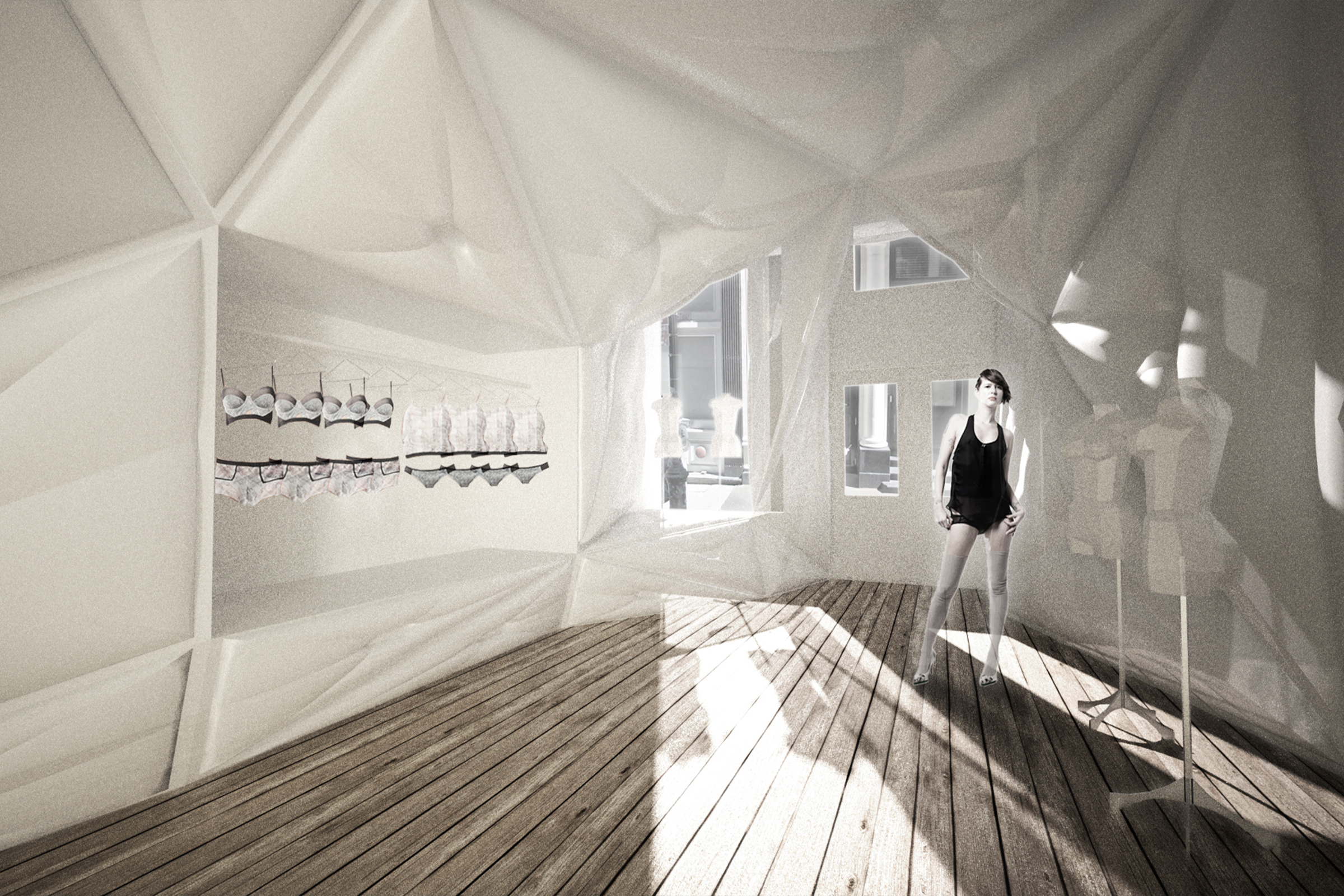

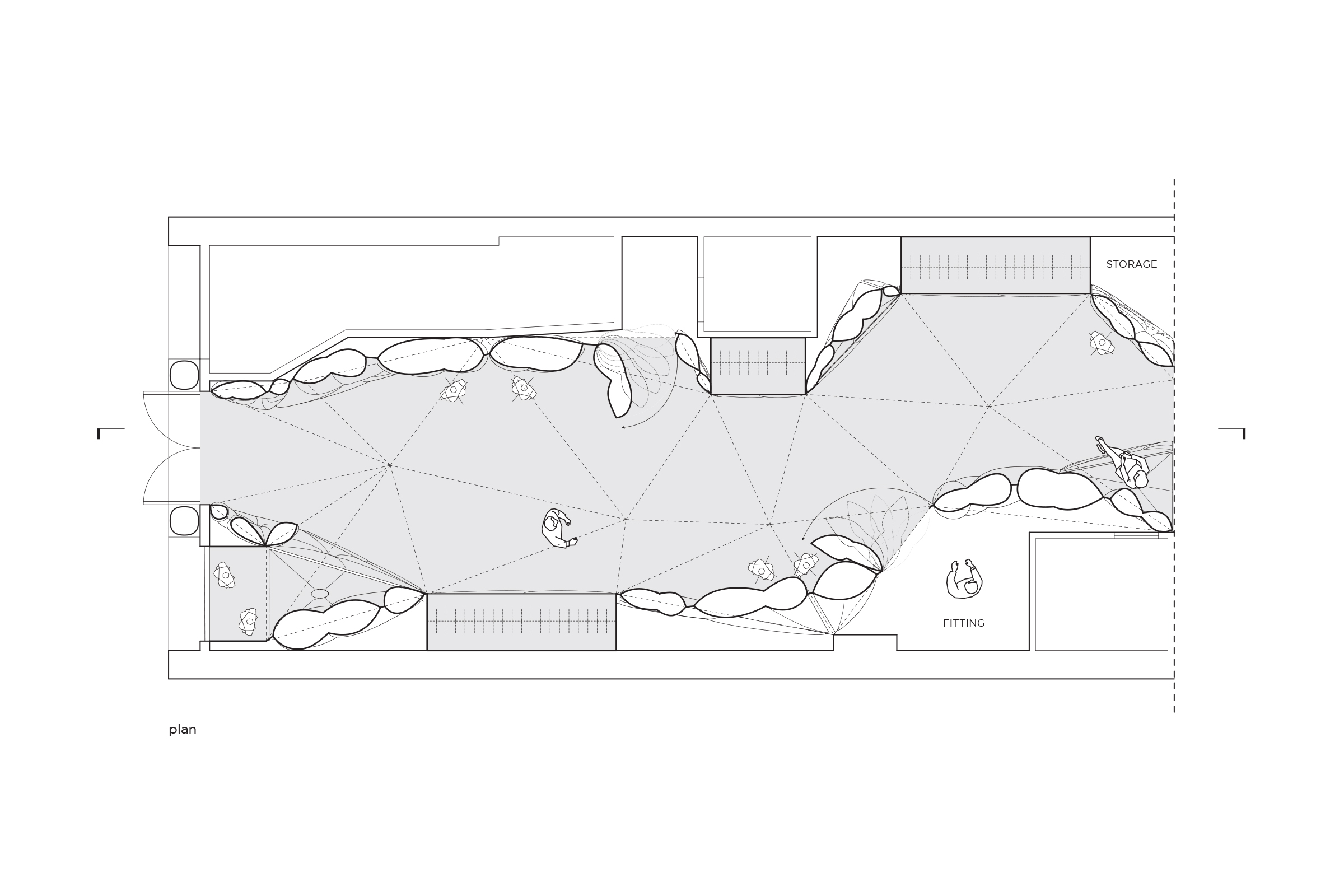

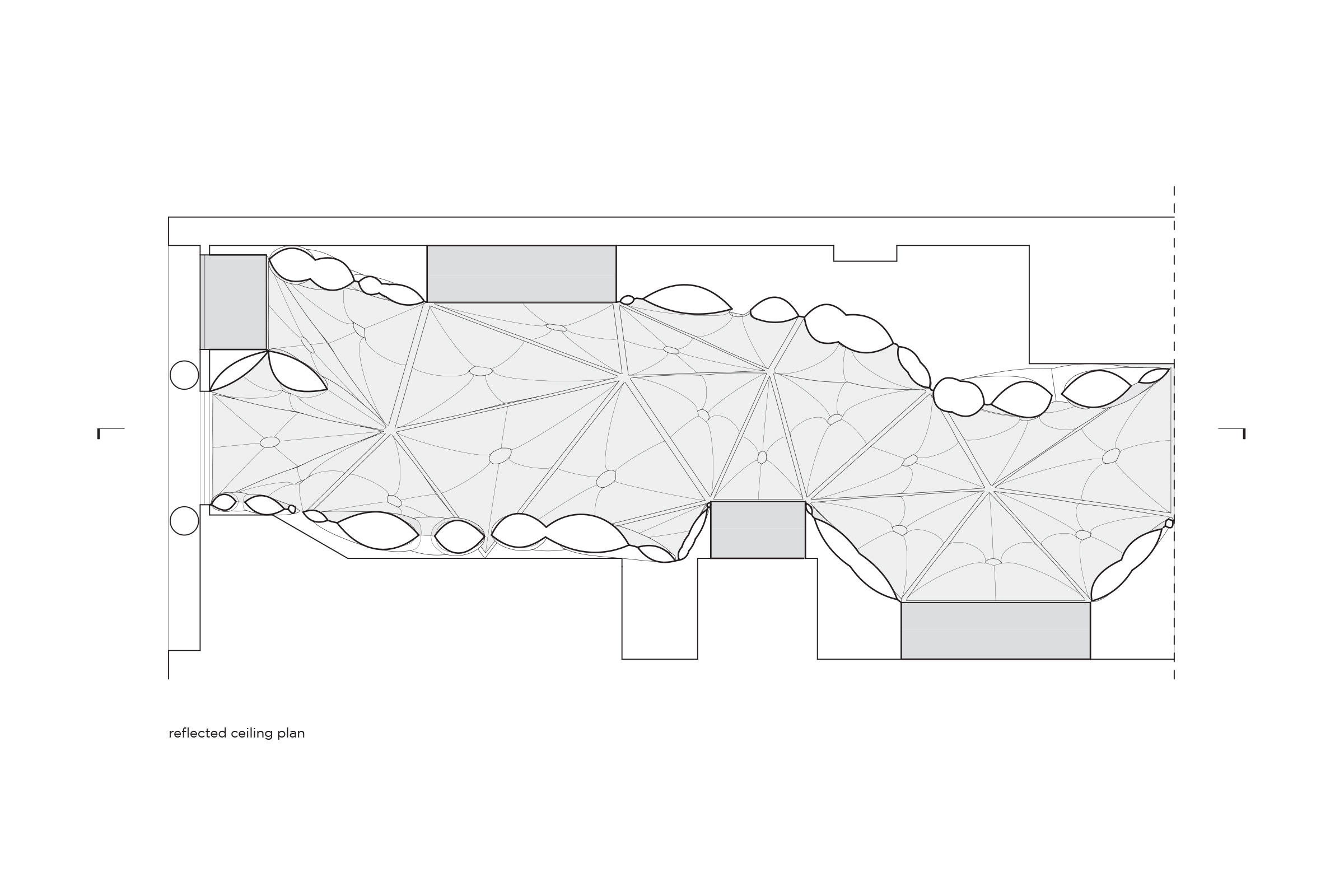

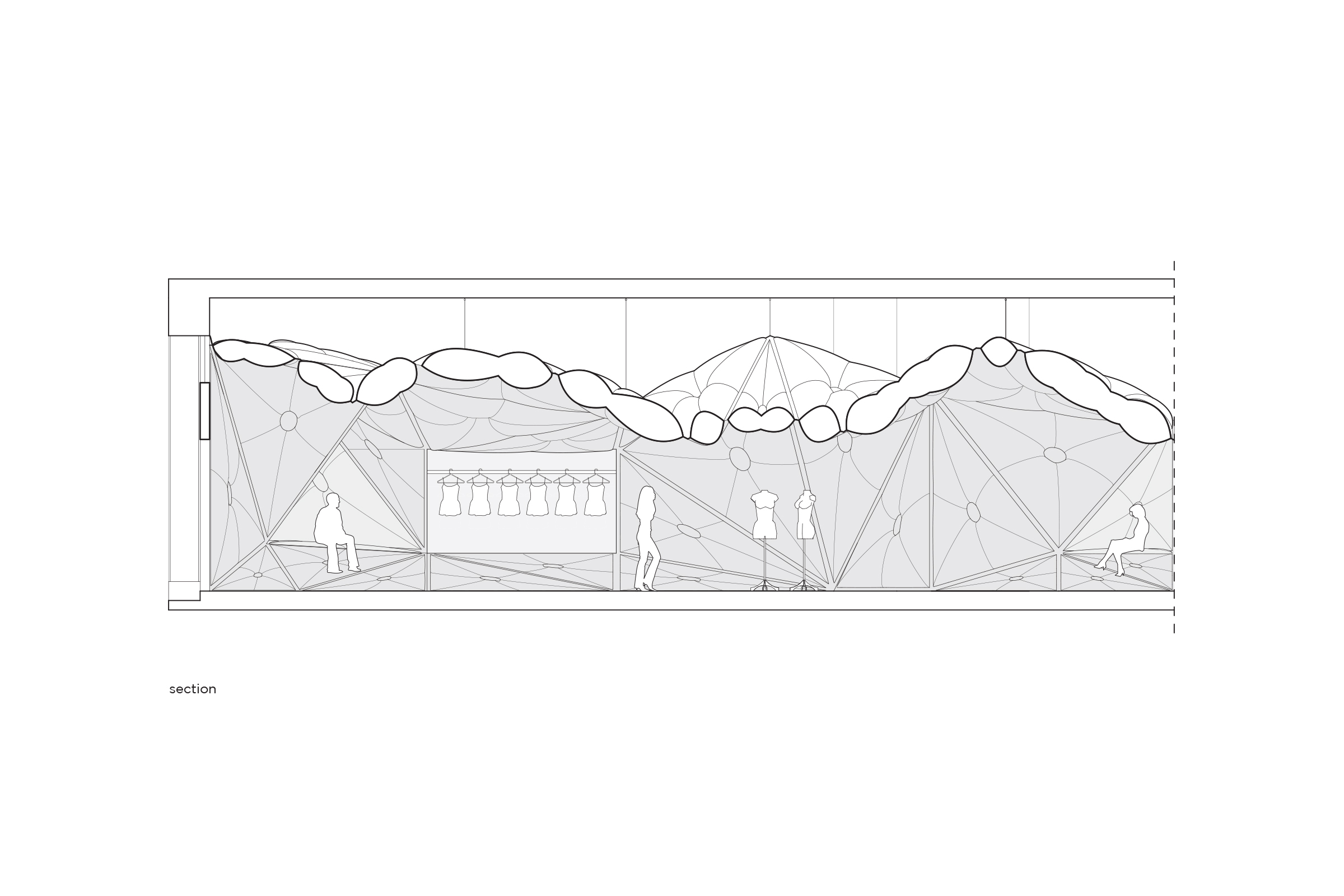

Pillow Fort creates a unique environment for shopping and exhibition beneath a luminous

blanket of inflated pillows. The blanket softens the geometry of the existing

room and creates residual spaces, which may be used for storage or trying on

garments. Alcoves are embedded within the blanket and may be configured to

accommodate various displays. Undulations reveal or conceal displays as one

moves through the space. The atmosphere is intimate, playful, and

unpretentious. The pillows are made of heat-welded polyethylene, a durable,

lightweight material commonly used in packaging. When backlit, the material

transmits a diffuse glow. The intensity of the light is modulated to create a

slow, pulsing effect, which alters the apparent weight and mass

of the blanket. Pillows are assembled into a network using grommets and

zip-ties. Zippers are used at select locations to provide access to spaces

beyond, including a changing room. In seating areas, the pillows are filled

with upholstery foam rather than air. Display alcoves are made of 1/4” white

acrylic mounted to steel frames. The aesthetic

is refined, yet distinctly temporary. In keeping with the design inspirations

and ambitions of Lake and Stars,

Pillow Fort

aims to create an environment that

is simultaneously dislocating and comforting. The pillows meter the space and

set up an infrastructure

for display that encourages exploration and interaction. The glow and

voluptuous forms of

Pillow Fort

provide a superb complement to the

monochromatic, architectural shapes of the Lake and Stars brand.

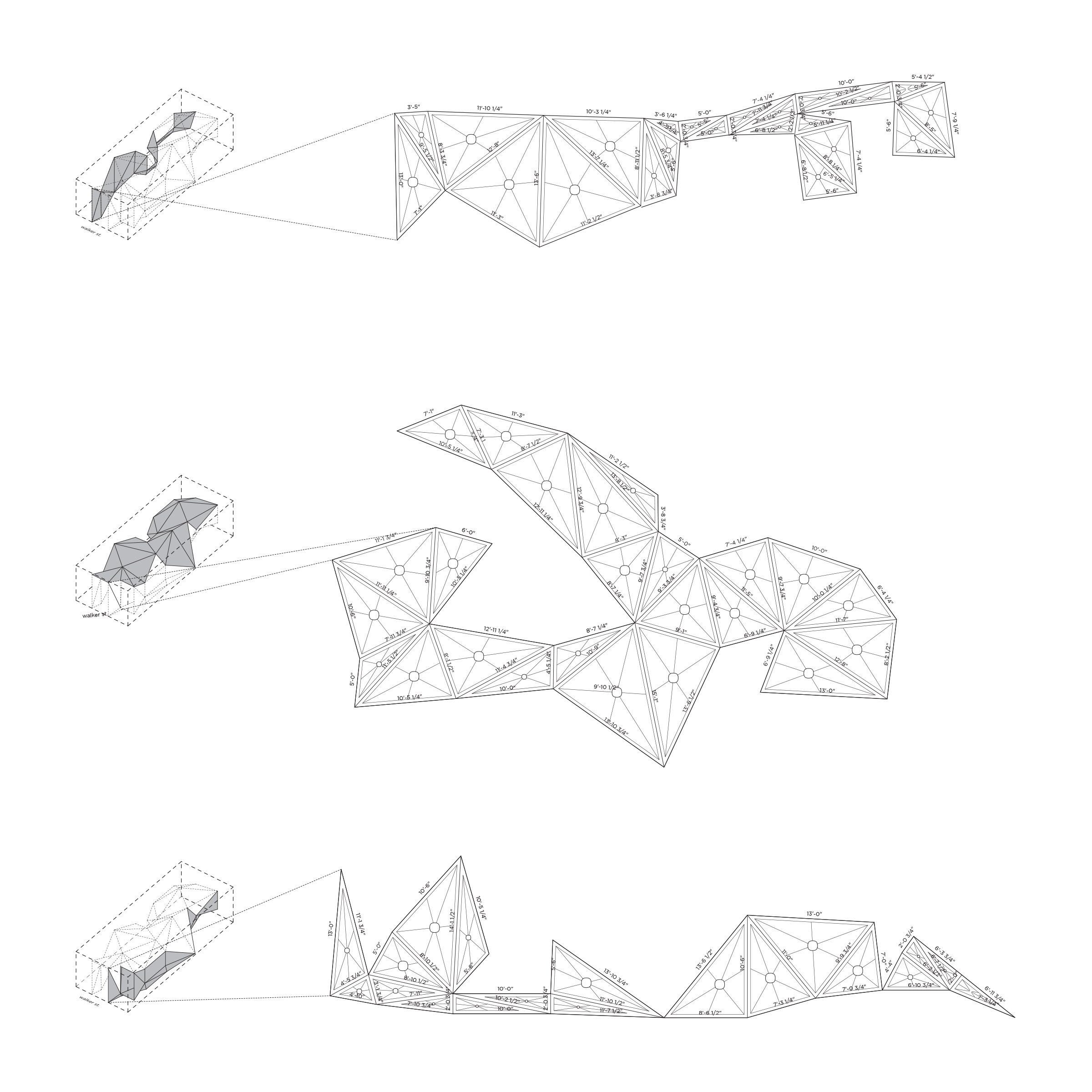

The overall system provides maximum effect with minimum material. It is lightweight, easy to transport, quick to deploy and requires little modification to the existing space. Polyethylene ASFR-6 is highly durable and meets NFPA standards for fire resistance. It is also fully recyclable. All primary components will be fabricated off site to minimize installation time.

murmur: Heather Roberge

The overall system provides maximum effect with minimum material. It is lightweight, easy to transport, quick to deploy and requires little modification to the existing space. Polyethylene ASFR-6 is highly durable and meets NFPA standards for fire resistance. It is also fully recyclable. All primary components will be fabricated off site to minimize installation time.

murmur: Heather Roberge

©2025

murmur