Shiatsu

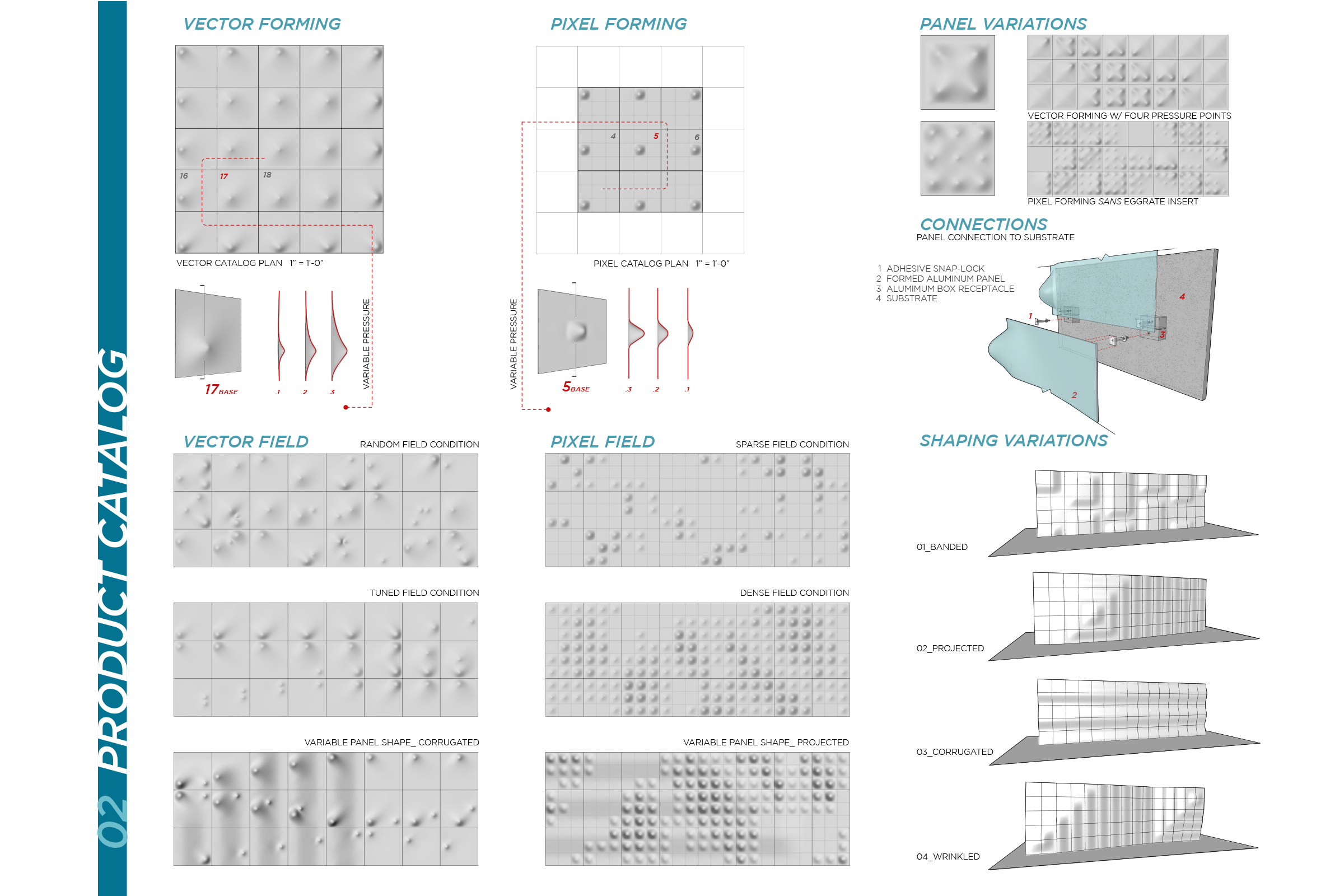

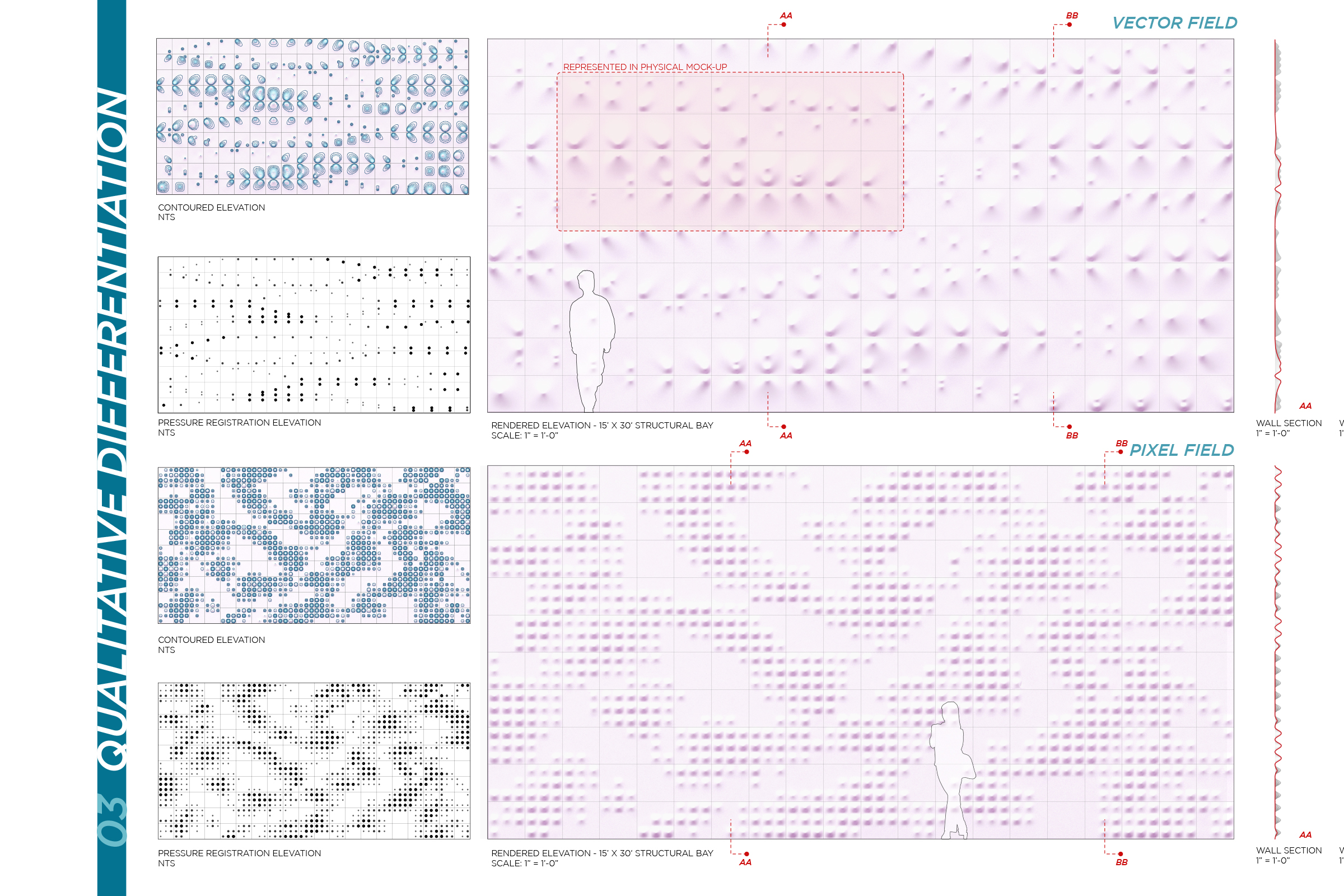

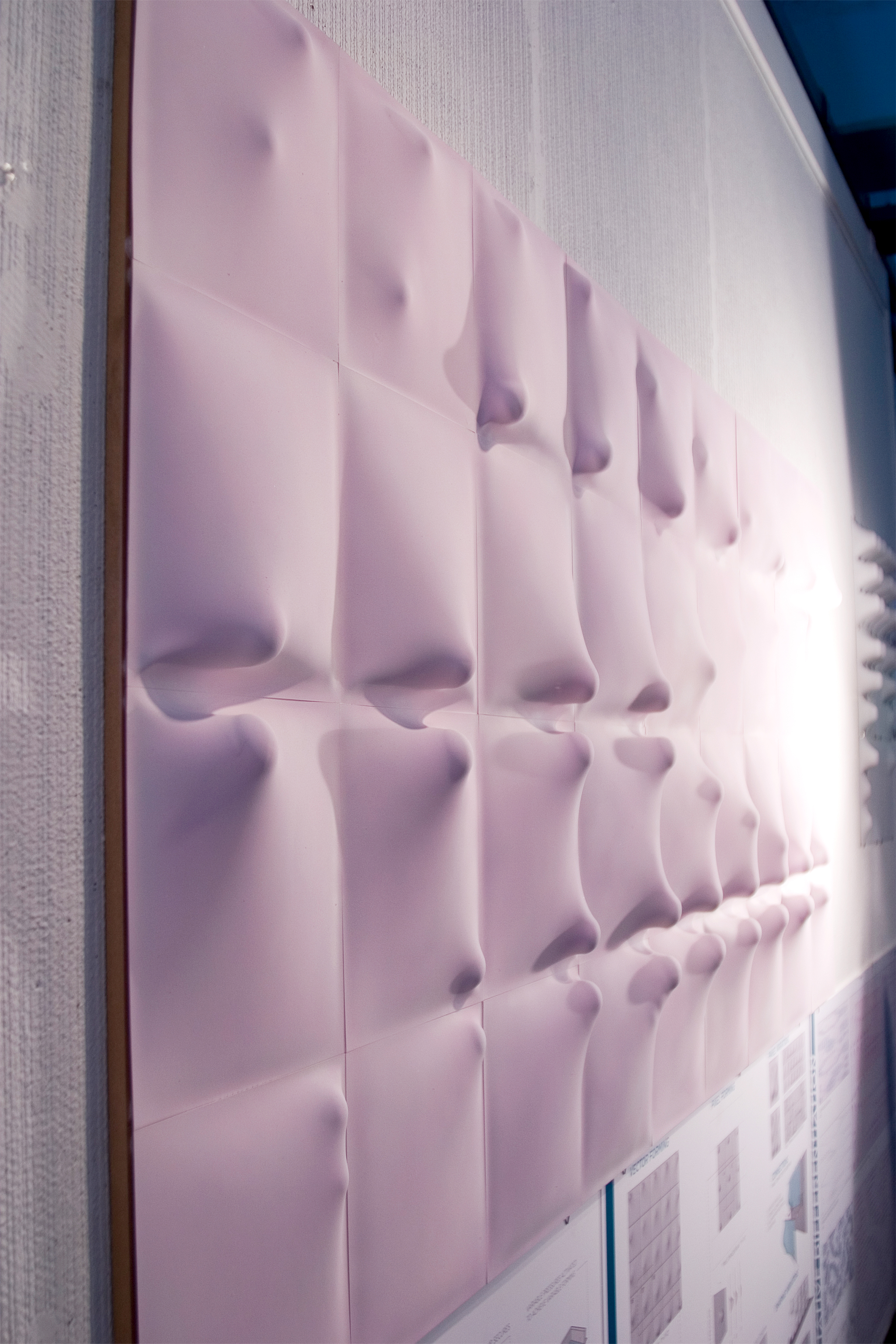

Michael Ben-Meir, Kyle Miller, Marcin SzefShiatsu challenges conventional superform technology processes by employing the concept of variable pressure to produce panel variation and ultimately, field complexity. By locally controlling the forming process, maximum variation can be achieved through minimal production of molds. In this research, we’ve employed three jigs brought together in one tool that aluminum can be formed over. Whereas conventional forming produces one panel type through one mold, this tool can literally produce hundreds of thousands panel types through converting the process of superform into a highly controlled art form. Shiatsu unearths a previously dormant capability of superforming aluminum and introduces new processes from which architectural componentry can be produced at maximum variety and minimal cost. Rather than reproduction, the variety of the end product allows for endless configurations and substrate mappings, thus further validating the use of variable pressure forming.